What are the differences between powder and granular organic fertilizer production line?

As the process part of the granular organic fertilizer production line, the main process of the powdery organic fertilizer production line is to ferment, crush, mix and package. The basic organic fertilizer equipment are dewatering machine hydration, dryer, fermentation equipment, crusher, mixer and package machine. Compared to the simple process of powdered fertilizer, granular organic fertilizer requires further processing.

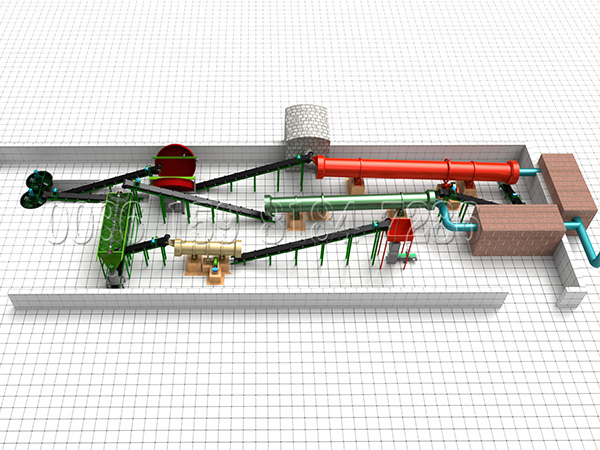

The basic process of the granular organic fertilizer equipment is dehydration, drying, fermentation, crushing, mixing, granulation, drying, cooling and packaging. It is necessary to configure an organic fertilizer granulator, an organic fertilizer dryer, an organic fertilizer coating machine and an organic fertilizer cooler. After being cooled, the granules can be packaged, stored or sold.

Zhengzhou Shunxin Engineering Equipment includes fermentation equipment, pulverizer, mixer, granulator, dryer, cooler, screening machine, packaging machine, etc. There are many types of equipment for manufacturing fertilizers, and different organic fertilizer processing equipment plans need to be formulated according to the different materials and capacity. Welcome to contact us for specific information.