Product details

The crawler type compost turner belongs to overground stockpiling fermentation mode, the most resource-saving fertilizer making pattern of construction & manpower. First pile the materials into long-strip stacks, then operate the compost turner to stir and crush the materials periodically, making organic matters degrade under aerobic condition. At the same time, this machine has the function of crushing, greatly reducing time and labour. So it improves the production efficiency & products quality and greatly lower the cost. This crawler type compost turner can efficiently mix sludge, chicken manure, culture and straw powder well, making a better aerobic environment for material fermentation. This machine has a faster fermenting rate than deep groove compost turner. And it prevents emitting of hydrogen sulfide, amine gas, benzazole and other harmful malodorous gas, and meets the environmental requirements.

- Performance characteristics

- This machine operates more easily, thus replacing hydraulic pressure type. It can save place, labour & diesel, shorten working hours and advance fermentation period.

- The clutch of this machine adopts soft start. ( The similar product in China all use hard clutch of iron to iron, which will result in damaging the chain, bearing and axle.)

- Retrofitting frontier hydraulic pressure push pedal, without spending time to stack manually.

- Roller hydraulic pressure lifting and falling. An air-conditioner can be installed in the driving cab.

- Working principle

The livestock manure, agricultural waste, filter mud, household waste can be turned into green environmental & soil texture-improving biological organic fertilizer through this compost turner by aerobic fermentation principle. It achieves heating in one day, deodorization & sterilization (completely killing worm eggs and germs) in 3 to 5 days, and making into fertilizer in 7 days. So it features faster fermentation rate, higher efficiency, compared with other mechanical fermentation method. It can add some auxiliary facilities such as automatic sterilization device according to customer’s requirements.

Working Video

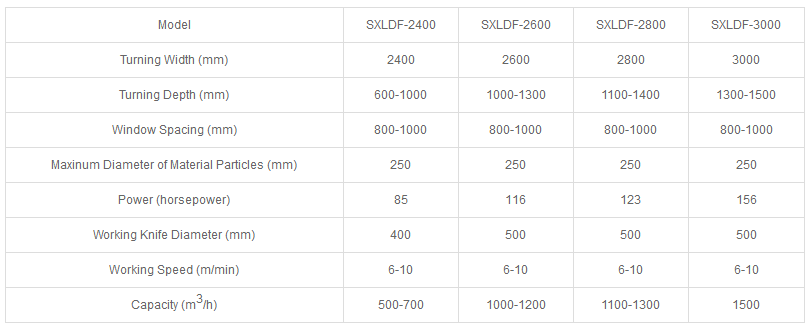

Technical Parameters